- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: shenzhen

- Brand Name: hesheng

- Model Number: 005

Quenching is one of the basic means to strengthen the steel, and the steel is quenched in the martensite, and then tempering to improve toughness, it is the traditional method to obtain high comprehensive mechanical properties of steel.

The metal workpiece is heated to a proper temperature and maintained for a period of time, then immersed in quenching medium in the rapid cooling of the metal heat treatment process. The commonly used quenching medium is salt water, water, mineral oil, air and so on. Quenching can improve the hardness and wear resistance of metal parts, so it is widely used in all kinds of work, mold, measuring and surface wear resistant parts (such as gear, roller, carburizing parts, etc.). With different temperature by quenching and tempering, can improve the strength and toughness of the metal loss and fatigue strength greatly, and can obtain coordination between these properties (mechanical properties) to meet the different requirements of the use of. In addition the quenching can also make some special properties of the steel have certain physical and chemical properties, such as the permanent magnet steel quenching to enhance its ferromagnetism, improve the corrosion resistance of stainless steel etc.. Quenching process is mainly used for steel parts. When the steel is heated above the critical temperature, the original structure will be changed into austenite at room temperature. Then the steel is immersed in water or oil to cool rapidly, and the austenite is transformed into martensite. Compared with other microstructure in steel, the hardness of martensite is the highest. The rapid cooling of quenching will make the internal stress of the workpiece, and when it is large to a certain degree, the workpiece will be deformed and even crack. To this end, we must select the appropriate cooling method. According to the cooling method, the quenching process is divided into 4 types, which are single liquid quenching, double medium quenching, martensite step quenching and bainite isothermal quenching.

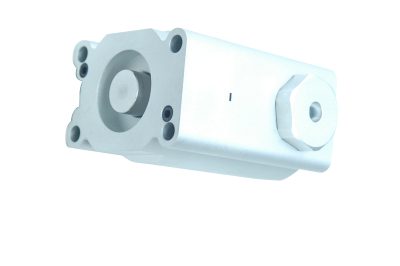

Hardware tools generally depends on the strength and stiffness of the tool, hardware tools after quenching, so that the stiffness of hardware tools are improved, and thus more durable, higher quality.

- Place of Origin: shenzhen

- Brand Name: hesheng

- Model Number: 005